Milfor Schwarte ATEX 1,000 Litre Processing Mixer with Platforms and Weight Cell System

Description

Originates from a European pharmaceutical leader in contract development and manufacturing (CDMO).

Includes:

304 s/s platforms and stairs

The MGW-1 used process mixer is designed for preparing alcohol, alcohol-based or water-based solutions, storing them, and maintaining the temperature of the medium at the level necessary for further processing.

Working Description:

Milfor is currently a part of Schwarte Processing – a brand of the HF FoodTech Group

Web: www.schwarte-processing.com

The device is made to ATEX standard and can operate zone classified as explosion-hazard zone standard Z1 and Z2.

The mixer is designed as a vertical cylindrical tank with a working capacity of 1000L and an internal diameter of 1100mm, ellipsoidal bottom.

The tank is a welded, double-shell structure made of 316L stainless steel (components in contact with the product) and 304 (components not in contact with the product).

The device is equipped with a pressurized heating jacket placed on the tank sidewall, enabling heating or maintaining the product temperature.

Water with a permissible pressure of 0.1 MPa will be used as the medium in the heating space.

50 mm thick Irpur E 33 polyurethane foam was used to insulate the mixer.

Technical Information:

Tank Working Volume: 1000 litre

Total Tank Volume: 1200 litre

Working Pressure: Hydrostatic MPa

Permissible Pressure in the Heating Jacket: 0.1 MPa

Total Tank Weight (without Raw Material): 370kg

Inner Diameter: 1100mm

Outer Diameter: 1216mm

Total Height: 2470mm

Mixer Power: 1.1 kW

Mixer Speed: 50 to 350 (l/min)

Floor Space Requirement 3600mm x 2700mm

Equipped With:

-STERIMIXER SMO 120/190 AC-CB magnetic stirrer, providing vigorous mixing. This magnetically coupled mixer is suitable for pharmaceutical, cosmetics and other applications and fully complies with GMP standards.

The SMO 120/190 rotor, with a diameter of 190 mm, is suitable for CIP/SIP processes.

Rotor material: AISI 316L/D1N 1.4435, polished to Ra 0.5 or better.

The magnetic stirrer was positioned and welded in accordance with APV's recommendations.

Detailed information regarding the stirrer's operation and maintenance is provided in the accompanying technical and operational documentation.

https://staitech.com/datasheets/Sterimixer-Data-Sheet.pdf

-High-hardness bearing system. The magnetic core is made of AISI 316 L/D1N 1.4435 stainless steel. The system is hydrodynamically designed for pharmaceutical applications.

-The SM A 120/190 drive unit consists of: 3-phase induction motor with Eexde I1BT 4 enclosure - reinforced housing terminal box, power 1.1 kW, supply voltage 380-420 V, 50 Hz, 1500 rpm - insulation class F with class B temperature rise - protection class: 1P 55 - top terminal box - magnetic rotor, bevel gear, and bayonet connection for easy servicing.

Welding plate, material AISI 316 L / 1.4435. Surfaces in contact with the product are polished to Ra 0.5 or better.

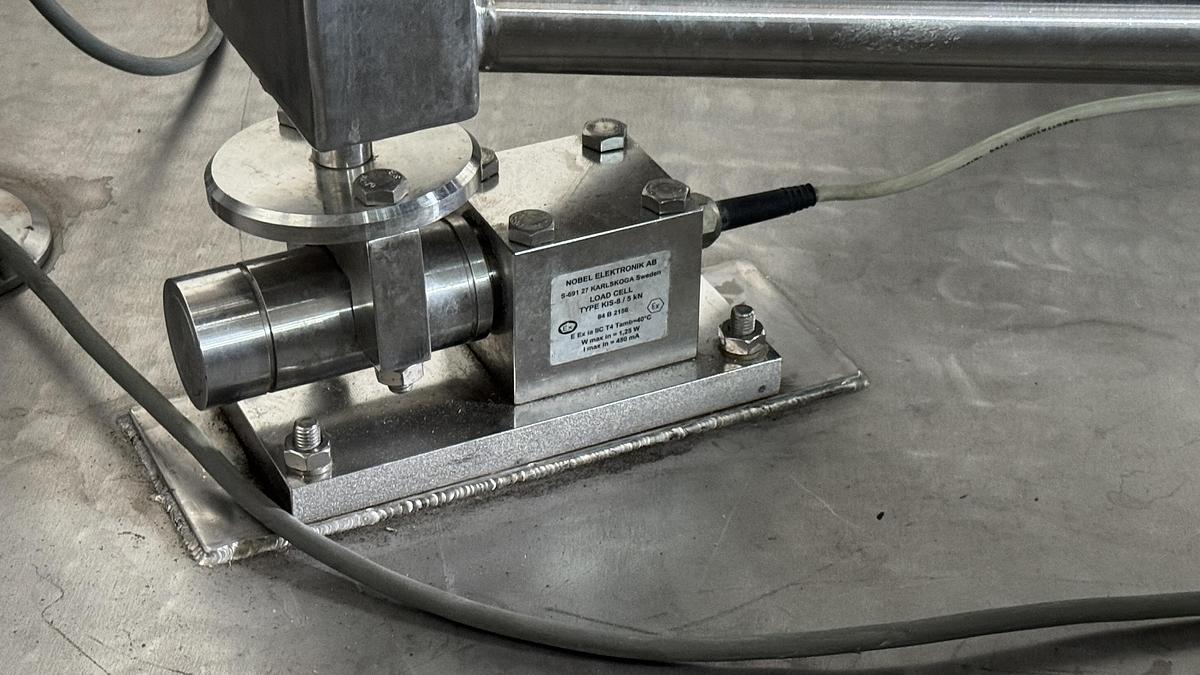

-SIMEX Weighing System / Weight Balance:

Scale type and construction: WZT/E4-3-1.2 - Ex

Measuring range: 1.2 Mg

Sensor accuracy: 0.1%

Safe overload capability: 50% Qn

Resistance to lateral forces: 100% Qn

Sensor MTBF: 20 years

Explosion-proof design of the sensors - EEx ia II C T4

The tank mass measurement system consists of three parallel-connected KIS-3 type load cells mounted in a star configuration under the mixer legs.

The weighing terminal with a ticket printer is connected to the sensor assembly.

There is an option for the new owner to fit a gas concentration mixture detector.

Dot Matrix Ticket Printer Type DPN-230.

Detailed information regarding the operation of the weighing system is provided in the accompanying Simex technical and operational documentation.

For the connectors – this Milfor Mixer is equipped with variety of connectors listed below:

· K1: aseptic manhole type P31-400 by BOYER

· K2: drain connection with APV membrane valve (silicone membrane)

· K3: filling connection, removable for cleaning, facing the wall.

· K4: spare filling connection

· K5: heating connection - outlet

· K6: heating connection – inlet

· K7: Spare fill port

· K8: Temperature measurement port with TOPEx-GB-100 sensor from KFAP

· K9: Illuminated sight glass with USL-06EX 50W/230Y lamp from Lumiglas

· K10: Ventilation port with APV diaphragm shut-off valve (PTFE membrane), ZO-50 breathing valve, and AR 5 flame arrester from Metalchem Kościan

· K11: Ventilation port with APV diaphragm shut-off valve (silicone membrane)

· K12; Removable cleaning nozzle with rotating Clip-On cleaning bowl

NW 25 LKSB 045 360° by Alfa Laval

· K13: observation window

The mixer is mounted on three height-adjustable legs made of 120 x 60 mm closed-section profiles.

Between the legs, the tank features tubular supports welded into its lower section, used to set reference weights and calibrate the weighing system.

Tags:

Atex Mixer

Alcohol Mixer

Specifications

| Manufacturer | Milfor |

| Year | 2000 |

| Condition | Used |

| Stock Number | PP1227 |