Nordson 3100V Hot Glue Melt System (For Closing Boxes and Cases)

Description

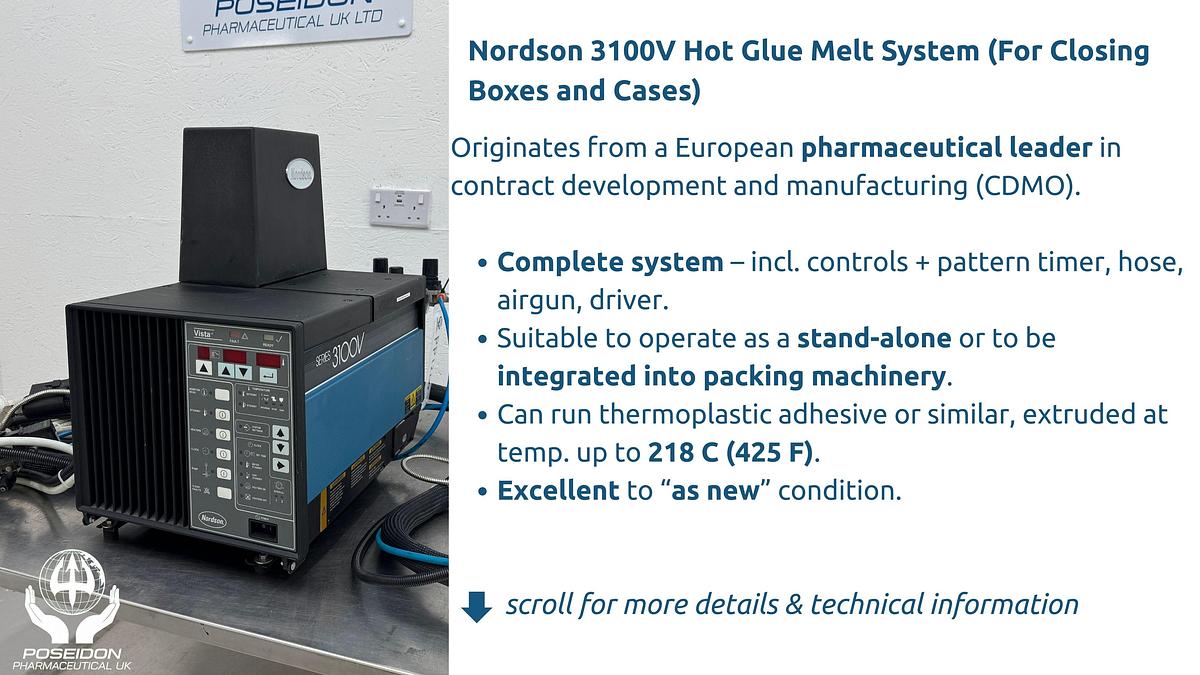

Nordson 3100V Hot Glue Melt System (For Closing Boxes and Cases)

3100 melter hot glue melt system – for packing process and closing boxes and cases, used in Pharma, Cosmetics, Packaging, Food, Nutrition, FMCG and other industries. Consists of:

- Melter

- Control panel

- Hose

- Air-operated gun

- Timer / Pattern controller

- Driver.

Suitable for thermoplastic adhesive or similar material that can be liquified and extruded at temperatures below 218 C (425 _F).

Technical Info:

The melter has three basic modes of operation: startup, operating, and standby. Each heated component (each hose, each gun, and the tank) is referred to as a zone.

The melter liquefies the adhesive, maintains it at the setpoint (operating) temperatures, and pumps it through hoses to dispensing guns. The guns apply the adhesive to the surface of the product or package. The guns may be automatically operated, by an air supply or an electric gun driver, or hand-operated.

Most automatic gun systems also use a timer or pattern controller to trigger the guns (when used in packing lines).

The tank, hoses, and guns are electrically heated: the tank by a cast-in heater element, the hoses by a spirally wound heating element, and the guns by a cartridge heater.

Series 3100 melters can be used to melt and pump almost any thermoplastic adhesive or similar material that can be liquified and extruded at temperatures below 218 _C (425 _F). The melters are not intended for use with polyurethane-reactive (PUR) adhesives because these adhesives require unique systems designed to prevent curing of the adhesive inside the dispensing equipment.

Machine Size: L: 650mm x W: 400mm x 600mm (H); W/T: 40kg;

Specifications

| Manufacturer | Nordson |

| Model | 3100V |

| Condition | Used |

| Stock Number | PP1200 |

| Machine Size | (L) 650mm x (W) 400mm x (H) 600mm |

| Machine Weight | 40kg |